When it comes to food safety compliance, restaurant operators (especially in the QSR industry) are divided between using digital systems for daily operations as opposed to physical logbooks. Around 87% of restaurant operators believe that switching their feet to technology during the inception of the global pandemic has helped their businesses survive in the midst of staffing shortages, safety protocols, and food safety compliance.

In a recent survey conducted by a popular tech solution provider, it was found that 40% of QSR operators are still using paper logbooks in this technology-driven era. Technology has always empowered every business by making them more accountable, efficient, and quickly adaptable to market dynamics. And, quick service restaurants are not exempted from the list. So, the question persists; why are some QSRs still using a paper logbook approach?

Impact of the pandemic on digital transformation in the restaurant industry

Quick Service restaurants cover the major restaurant industry market in the U.S.A. The statistics show that the count of QSRs has decreased from 193,995 to 186,290 in the United States in 2020. The sudden decline is blamed on the coronavirus pandemic. But many QSRs report that leveraging technology has benefitted them significantly.

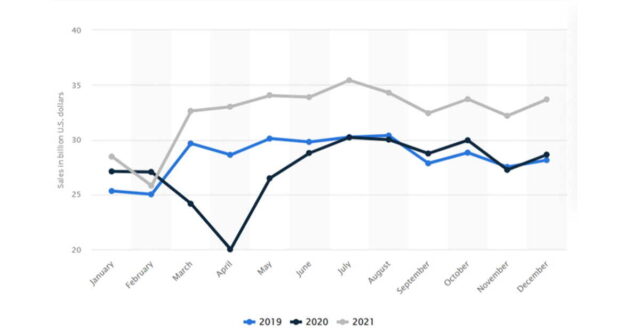

The revenue generated by these QSRs during the pandemic had its highs and lows. According to a report by Statistica.com, the year-over-year report of the QSRs represents declines from 2019 to 2020, emanating from the pandemic. In March 2020, the first sales drop was witnessed with a decline from 29.66 billion U.S. dollars in 2019 to 24.16 billion U.S. dollars in 2020. However, with aid of digitalization, surprisingly these sales metrics picked up to better the pre-pandemic levels by 2021 with 30 billion US dollars.

The dwindling sales, lack of human resources, and new challenges with respect to changing consumer behavior forced businesses to adapt to technology in a way they had never experienced before. Digital transformation was accelerated by a need for survival more than profitability. As part of the digital transformation in the restaurant industry, technologies like self-serve kiosks, digital ordering systems, interactive menus, contactless payments, food delivery, and digital operations management systems were implemented across several locations. Restaurant operators who had been hesitant in investing in technology finally gave in to the need to change for the future and they are now enjoying the returns on their investment.

The recent pandemic has thus brought a wave of the digital revolution into the restaurant industry, where we have witnessed a massive digital transformation around the world. The QSR’s drive towards digital transformation to adjust to the “new normal” is here to stay and will impact the way these restaurants respond to market dynamics.

Barriers to implementing digital food safety systems in QSRs

When people consider digital food safety systems, they only perceive it to be a digital version of the paper logbook that they are so accustomed to using in their daily food safety inspections. However, a digital food safety system has more features and capabilities than simply recording data in a digital format. For example, a digital system will not only provide alerts for non-compliant cases but will also create action plans aligned with the restaurant’s SOPs. This is just one of the features that differentiate the digital food safety system from a regular manager’s logbook.

When the manual food safety practices were digitized into a centralized software system, Digital food safety systems came to rise. These systems might include temperature logging with probes, automated labelling, food safety checklists, cleaning checklists, and temperature monitoring.

The pandemic brought a breakthrough for the brands to get digitized and digitalized. This increased their real-time visibility and allowed multi-unit managers to monitor compliance across several locations easily without having to physically travel to each location.

There are several barriers that are preventing most restaurant groups or locations from moving to a digital system for operations. While these factors are attributed to different aspects of operations and management, the common factor is “CHANGE”.

Let’s take a look at some of the possible reasons behind this hesitation to adopt a digital food safety system.

Resistance to change

This is probably the biggest barrier to implementing a digital food safety system in a restaurant. The digital divide between the older generations and the millennials as well as Gen Zs has created a significant barrier in terms of accepting the digital transformation. While millennials and Gen Zs are more accustomed to using technology to make their lives easier, the older generations prefer a manual approach to the same tasks.

In addition to this, the presence of the older generation in the key management positions also hinders flexibility in the adoption of digital systems as they hold the key decision-making power as well. The resistance even relates to the fear of failure. For instance, a Senior multi-unit manager of a QSR will resist the use of a Bluetooth thermometer in recording equipment temperatures where they believe this is avoidable as the temperature can be recorded manually as well.

Fear of metrics

Most surveys and studies have discovered that the fear of metrics is one of the biggest challenges for businesses in terms of migrating to a technology-driven solution. The angst about being recorded and tracked is something that the crew members fear a lot. As per an article by Computer Weekly, a recent study by Microsoft reveals that the new business technological changes affect 61% of employees with anxiety. This anxiety leads to job insecurity.

The primitive pencil-whipping made it challenging to trail the wrong footprints, as the crew members might sometimes miss a scheduled task. But, with the digital systems, any missed task will be duly notified to the manager. As a part of pencil-whipping, the managers use to complete the records of logbooks on their way back home from work. Manipulation and mishandling of data were seen more often.

Digital records restrict any loophole in food safety compliance and toll on the freedom of any employee.

No mandate by the brand

Food safety inspections reveal the true state of compliance and preparedness of any QSR. While most brands or parent companies of QSR brands have never openly acknowledged an approved digital solution, they have always emphasized the need for documenting daily food inspections and tasks as part of their guidelines. Due to this, most QSR operators have assumed that the physical logbooks are mandated by the brand, whereas there is no such requirement for digital systems. The fact, however, is that brands only require documentation, compliance, and preparedness. Going digital or sticking with paper is a choice that QSR operators are free to make as per their preference.

Digital systems reduce stress, instil accountability in team members, provide a world of data in a single report, and offer the opportunity to become more cost-effective.

Investment in technology can be avoidable

The cost of maintaining and operating a QSR is already assumed to be sky-high, which includes increasing food costs, high employee turnover, and maintenance costs. QSR owners believe that investing in technology would add more to the already increasing expenses of the restaurant and thus consider it avoidable.

It is believed that investing in technology for QSR’s technological investment branches up to the cost of digital training of employees, the cost of the digital devices, maintenance, and much more. For example, the training of employees for a particular technology brings risk as well as extra costs to the restaurant.

No defined standard operating procedure (SOP)

The traditional method of pencil-whipping never mandated any of the QSR to have an ascertained SOP. These are a set of detailed instructions that describe the operations, industry regulations, brand standards, and voluntary standards. Prior, it was always believed to be excessive paperwork and a decline in workplace individuality.

Since digitalization, it is mandatory for businesses to possess an SOP. These act as the guiding light for better compliance and training. For instance, if a guideline under highlights the temperature to be recorded in the morning, this task has to be completed within defined time limits. An alert/notification for the expired task is sent to the manager and corrective action will be performed on time. SOPs that are well-defined and well-written is critical for making more informed decisions.

Successful QSRs have improved operations and compliance with digital food safety solutions.

Lately, in the first quarter of 2022, Daddy’s Chicken Shack is a tech-forward fast-casual growing brand based in Pasadena, California. The brand has recently taken steps towards investing in dual-production lines, digital customer feedback technology, and geofencing. It is even working now on a cloud-based POS.

Evidently, leveraging technology and transforming digitally has been a gold mine for many QSRs and restaurants. Technology has helped these QSRs to gain ground in various aspects like an increased focus on food safety compliance, better training, increased employee engagement programs, and digital health monitoring. The need for QSRs and restaurants to evaluate the need for and benefits of pivoting digital has become urgent.

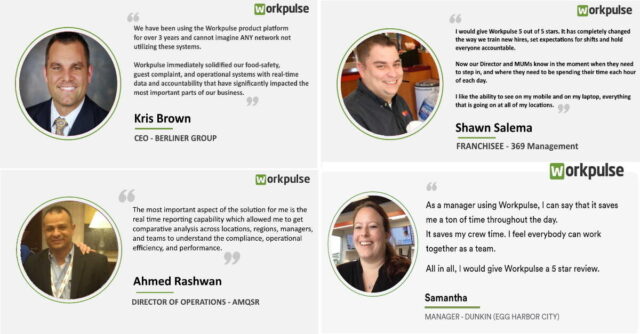

It’s easy to comment on the fact that successful QSRs have adopted the technology. However, it is better to show the true impact digital solutions have had on people, processes, compliance, and efficiency.

Check out some testimonials from leading QSR professionals.

Take your first step towards digital food safety with workpulse

In this Tech-savvy era, if you are still working on recording the data in manual logbooks and relying on manual references, then it’s high time for you to transform digitally. You are just one decision away from being tech-forward in the restaurant industry.

Schedule a consultation with us to find out how the Workpulse platform can help your QSR go digital.