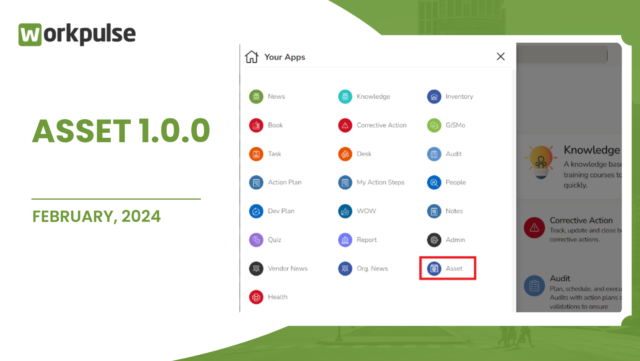

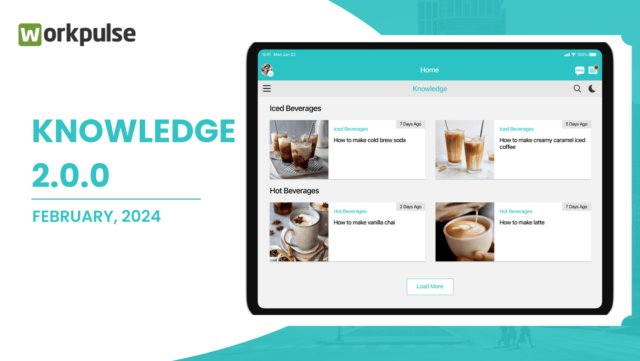

Workpulse Ordering & Production Management System

The Workpulse Ordering and Production Management system powered by PAROS provides a platform for CMLs to manage the various stages in the manufacturing process and product life cycle efficiently.

With our system, you have access to accurate sales data, operating costs, information about the status of critical items in your supply chain, and your inventory levels.

The OPMS Production module lets you quickly review production orders, raw material (ingredient) requirements, inventory levels, and provides you a production manifesto that is broken down in optimal batch sizes based on throughput rates/capacities of your various equipment.

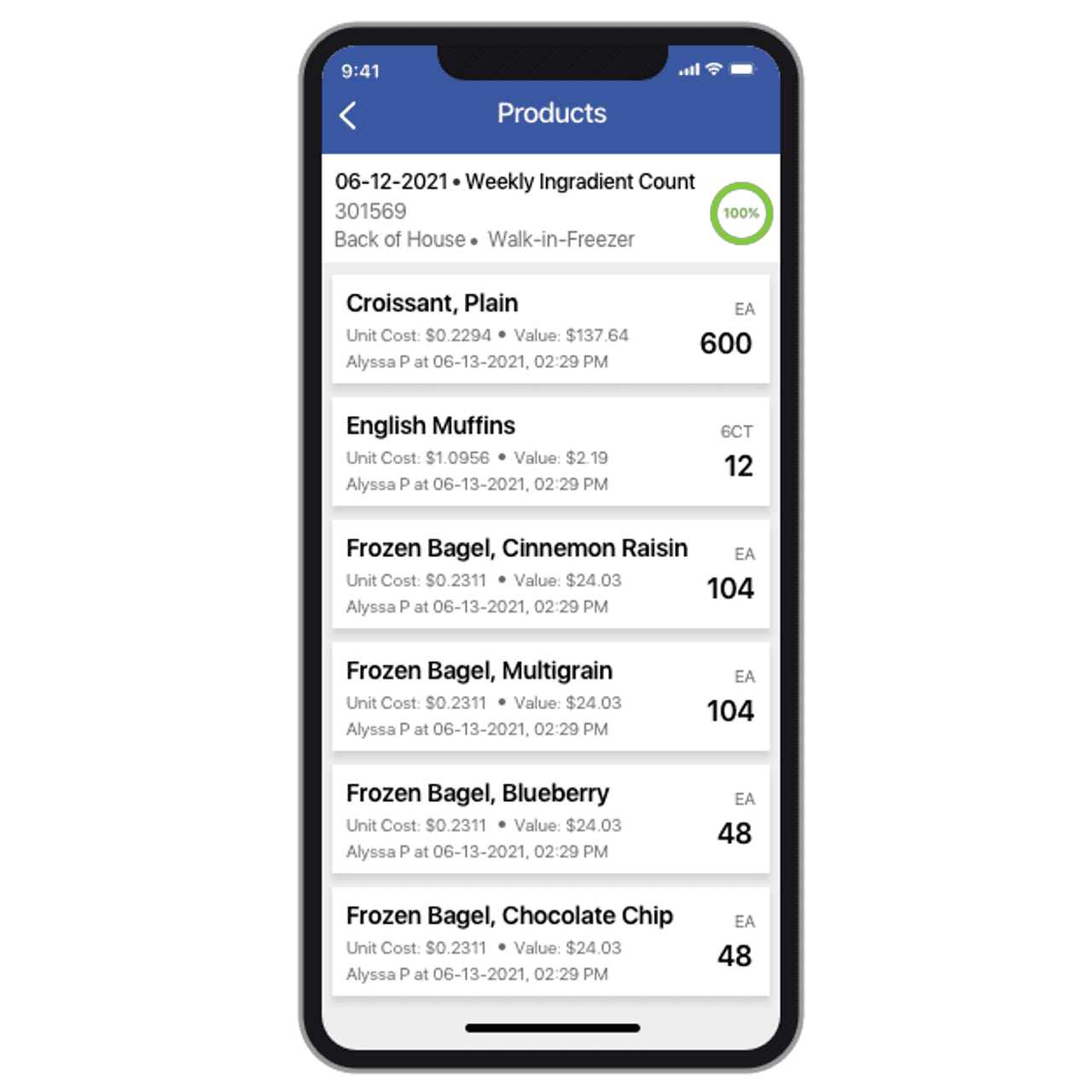

The Inventory module helps you maintain adequate, but just-in-time levels of raw material (ingredient) inventory. Now you can accurately forecast all raw material needs for your bakery and be prepared for any expected surge in orders.

Get complete visibility on production, order management, costing, wastage, and delivery with easy-to-use solution. Schedule a call with our consultants to learn more about the Ordering and Production Management system.

Why Choose Workpulse?

Efficient Order

Management

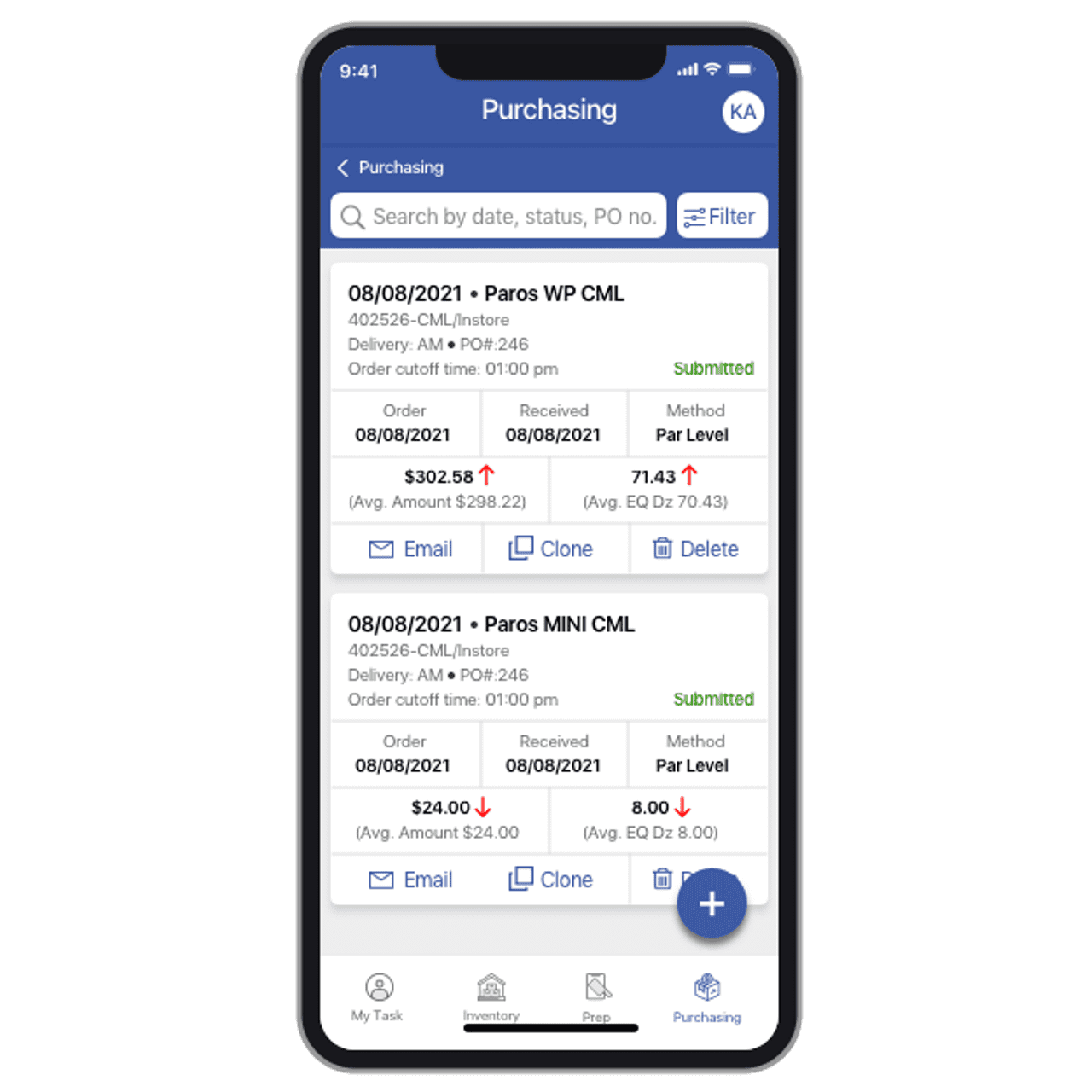

Eliminate errors in orders completely by giving control to your stores to order online from any device, anytime. Identify and setup minimums, rounding controls at the vendor levels. Auto generate par level or forecast store orders. Manage credit requests online, be more efficient and save time.

Key Performance

Metrics

Look at information the way you want with the Ordering & Production Management System. All reports are built on a powerful reporting engine, giving you ad-hoc capability. Export key reports to csv or excel, pdf, print or email. Easily access real time reports and actionable data to make informed decisions on time.

Accurate

Costing

Accurate product costing is critical for the survival and success of your business. Track your costs from the moment you receive the raw materials to the delivery of the finished products. OPMS provides detailed reports to stay profitable and make informed decisions about pricing to achieve the desired profit margins.

Production & Inventory Management Features

- Global Item Management

- Recipe Management

- Manage new, discontinued, seasonal products

- CML, DCP and other vendor catalogs

- Price changes

- Marketing and new product introduction

- Cost or yield change in product affects all related products

- Maintain recipes and multi-level recipes for each production batch based on recipe for each product and various production processes products easily

- Production Management

- Inventory Management

- Production and finishing reports based on orders

- Set up waste factor to automatically adjust the production

- Configure batch size for mixing to generate batch mixing reports

- Record batch mixing temperatures and processing time

- Real time ending inventory

- Compare ideal to actual food cost

- Material requirement planning

- Manage your food and yield variance

Order Management Features

- Sales Orders

- Forecasting

- Auto ship products to introduce new products to stores

- Manage production lists, substitute/delete products

- Generate invoices seamlessly

- Accommodate and invoice pickup customers

- Forecast orders days ahead for better planning with usage history

- Exclude a day from forecast

- View usage history and items with zero waste on a forecasted order

- Reports to help reduce wastage and meet merchandising standards

- Online Ordering & Credit Resolution

- Analytics & Reporting

- Auto generate orders to help with forecasting

- User friendly ordering screen to easily place/review/edit orders before cutoff time

- Easily place special orders for one off order and exclude it from forecast

- Easy to use online credit resolution

- Exclude location specified blackout dates

- Manage your in-store bakery prep and waste easily

- Enterprise level reporting for production, finishing, packing, and invoicing

- Setup email profiles to have weekly reports emailed automatically on a weekly close

- Menu analysis to help with costing and pricing of current and new products

- Manage your food and yield variance with inventory insights

- Enter weekly payroll and monthly fixed expense to generate weekly CPD (Cost Per Dozen)

- Flash profit and loss on monthly/weekly basis

Book a FREE CONSULTATION

Get in Touch

Address

Gibbsboro, NJ 08026

Call us

(For Sales & Support)

sales@workpulse.com