Restaurant owners rarely have a proper preventative maintenance plan set up for their stores. Despite losing a sizeable amount every year on maintenance costs, employee training costs, and equipment replacement costs, most restaurants do not have a proactive maintenance plan in place. The reason – a reactive approach to maintenance which can lead to huge costs. While restaurant owners are not oblivious to the benefits of preventive maintenance, they fail to realize the importance unless they truly understand the cost impact of unplanned maintenance.

Understanding the cost of reactive maintenance

With an unplanned maintenance, restaurants only focus on issues when they become major hurdles in day-to-day operations. The emergency repair of equipment may not seem like a huge cost initially, but when you understand the implications of other hidden costs associated with it, the potential savings will be startling. Moreover, the problem with reactive maintenance is the lack of accountability as the problems may go unnoticed or the vendors may fail to resolve the issue on time, leading to further expenses and loss of sales.

Some of the hidden costs involved in reactive maintenance include:

- Decrease in equipment lifespan (leads to depreciation of asset and increased investment on equipment)

- Downtime of equipment (leads to loss of sales)

- Food wastage (leads to high resource costs)

- Loss of employee hours (leading to reduced productivity and dissatisfaction)

In some cases, the problems may even cause the location or the restaurant to shut down. All of the above costs (when added) come out to be a massive expense which can easily be saved by adopting a proactive approach to maintenance. Strangely, the problems are allowed to grow into huge problems due to the ignorance of initial signs of damage.

The best way to understand the real cost of unplanned maintenance, you need to use the Avoided Cost formula.

The formula is:

Avoided Cost = Guest Checks Per Hour x Average Cost Guest Check x Repair Time

In order to use this formula, let’s take the example of the breakdown of a commercial fryer in a QSR location. For the purpose of calculating the avoided cost, the following are considered.

- Guest checks per hour (on the day the equipment failure was reported) = 20

- Average cost per guest check = $10

- Repair time for equipment = 4 hours

On the basis of the above-mentioned assumptions, the avoided cost or the cost of unplanned maintenance for the commercial fryer at the location comes out to be:

Avoided Cost = 20 guest checks (per hour) x $10 (average cost per guest check) x 4 hours (repair time) = $800

The actual cost could be higher depending on the different variables used in the equation. Moreover, if the equipment is found to be unfit for repair and has to be replaced, then that’s a direct cost added to the monthly budget. The impact of unplanned maintenance is that the lifespan of equipment is roughly reduced to 50% and restaurants may end up spending more than $10,000 for replacing the equipment well before its intended expiry.

By implementing a preventive maintenance plan, you can save money on major repairs or replacement. If you have multiple locations for your franchise, then the cost would increase exponentially.

Why should you choose preventive maintenance?

Preventive maintenance is a proactive approach to extending the lifetime of equipment with the use of adjustments, cleaning, lubrication, repairs, and parts replacements. By regularly inspecting the assets and reporting an issue in real time, the problems can be resolved quickly without allowing it to grow into bigger issues. One of the biggest advantages of implementing a preventive maintenance regime is avoiding shut down or down time caused by emergency repair of equipment.

Preventive maintenance usually has the following types:

-

Calendar based maintenance

This is a recurring work order that can be scheduled in a maintenance management system where the inspection and repair is done as per a predefined cycle.

-

Usage based maintenance

This refers to maintenance being done after a specific usage of the equipment. For example, if a coffee machine has been used to brew coffee for 1000 times, then the machine would be scheduled for maintenance.

-

Predictive maintenance

This refers to the analysis of historical data for the particular equipment in order to identify maintenance requirements. Every equipment will have its own trend and using it to plan a dedicated maintenance schedule would prove highly useful to extend its effective life.

-

Prescriptive maintenance

This is similar to predictive maintenance, except for the additional use of dedicated software to assist with the planning of maintenance activities based on trend analysis.

Preventive maintenance helps to extend the life of all assets in a restaurant, improves operational efficiency of equipment, and causes fewer equipment breakdowns. All of this leads to cost savings across all locations. Additionally, preventive maintenance helps to schedule repairs during off-hours to ensure minimal disruption of daily operations. It also gives you the option to schedule maintenance as per non-emergency service cost. Usually, emergency repair charges are 200% of the standard rates.

The cost impact of preventative maintenance can be calculated using the following formulae.

Avoided Cost = Guest Checks Per Hour x Average Cost Per Guest Check x Repair Time

Preventive Maintenance Gain = Repairs Not Needed Per Year ($) + (Replacements Put Off ($) / Years of Increased Expected Life) + Avoided Cost Per Year ($)

The avoided cost calculation has been presented in the previous section. Let’s calculate the preventive maintenance gain using the provided formula.

In order to use this formula, let’s take the example of the breakdown of a commercial fryer in a QSR location. For the purpose of calculating the preventive maintenance gain, the following are considered.

- Repairs not needed per year = $2,400

- Considering the example of the commercial fryer, the average repair time is 4 hours, maintenance is required 3 times a year for the fryer, and each service cost is $200 per hour. Based on this, the value of repairs not needed for the commercial fryer is (average repair time x annual maintenance requirement x cost per service) $2,400

- Replacement avoided = $4,000

- Years of increased expected life = 3 years

- If the average equipment life of the commercial fryer is 7 years and with proper maintenance, the expected life increases to 10 years, then the increased expected life is 3 years.

- Avoided cost per year = $2,400

- From the avoided cost calculation in the previous section, it was found that the avoided cost for each maintenance of the commercial fryer is $800. If the maintenance requirement per year is 3 times, then the annual avoided cost (savings) is $2,400

On the basis of the above-mentioned assumptions, the preventive maintenance gain for the commercial fryer at the location comes out to be:

Preventive Maintenance Gain = $2,400 + ($4,000 / 3) + $ 2,400 = $6,133

From this calculation, it is evident that by simply performing preventive maintenance on the commercial fryer, a restaurant would be able to save $5,000. Now you can imagine the collective preventive maintenance gain of all the equipment at all locations of your restaurant. Yes, the amount is massive and that is exactly what you can save.

Understanding the cost of preventive maintenance

Now that you know how to calculate the savings from preventive maintenance, it is important to understand the actual costs involved in it as the maintenance will incur some cost. The major component of preventive maintenance costs is based on the labor costs. Additionally, there might be a need for getting professional technicians to service the equipment.

In order to calculate the cost of preventive maintenance for each equipment, you need to use the investment base formula.

Investment Base = (Labor Cost Per Day x Days Open) + Annual Training Cost + Annual Professional Service Cost

In order to use this formula, let’s take the example of the breakdown of a commercial fryer in a QSR location. For the purpose of calculating the investment base, the following are considered.

- Labor cost per day = $15

- Considering an hourly wage of $15 and the maintenance time for the commercial fryer to be 60 minutes, the labor cost per day comes out to be $15

- Days open (annually) = 300 days

- Considering the business operates for 5 days a week and is operational throughout the year (52 weeks), the total days open comes out to be 300 days.

- Annual Training Cost = $75

- Considering that 5 employees are required to perform maintenance in the restaurant and they require 60 minutes of training to learn proper maintenance, the annual training cost comes out to be $75

- Annual professional service cost = $400

- Considering the service cost for the commercial fryer to be $200 per hour, and a total requirement of 2 hours of professional maintenance for the equipment, the annual cost comes out to be $400

On the basis of the above-mentioned assumptions, the investment base for the commercial fryer at the location comes out to be:

Investment Base = ($15 x 300) + $75 + $400 = $4,975

So, the preventive maintenance cost for the commercial fryer (as per the example) would come out to be $4,975 per year.

Calculating preventing maintenance ROI for your restaurant

With the above calculations, you will be able to get a clear understanding of the cost saved as well as the actual cost of preventive maintenance for your assets.

In order to calculate the ROI of preventive maintenance, you need to use the following formula.

Restaurant Preventive Maintenance ROI = Preventive Maintenance Gain / Investment Base

The values for preventive maintenance gain and investment base can be taken from the calculations made in the previous sections.

Restaurant Preventive Maintenance ROI = $6,133 / $4,975 = 1.23

As per this calculation, the ROI based on the example of the commercial fryer comes out to be 1.23 which is 123%.

Any return on investment above 2% is considered good. As you can see that with preventive maintenance, the ROI is 123%. Knowing that with preventive maintenance, you can now get a huge return on investment, would you still continue using unplanned maintenance for your restaurant?

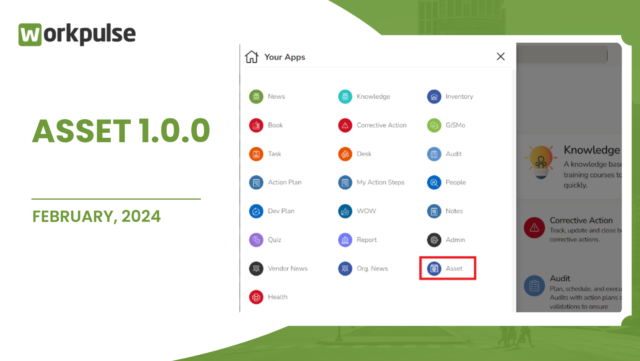

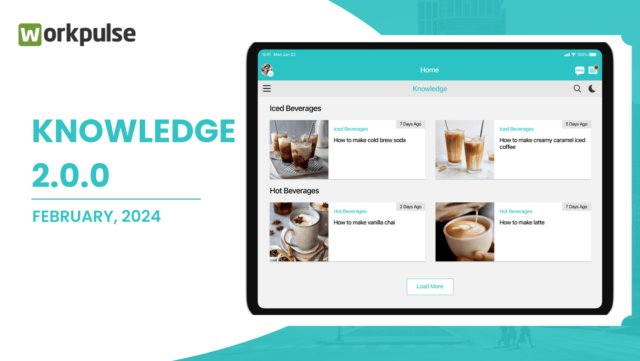

Digital preventive maintenance solution

Workpulse offers a robust digital preventive maintenance solution that leverages technology to help you implement the mechanism effectively, enforce accountability, get visual evidence of competition of maintenance, view expense summaries for each service / individual / equipment, and implement a proactive approach towards maintenance of equipment.

The benefit of using the Workpulse platform is that you can save even more on training cost as the SOPs are defined in the solution and onboarding requires less time than traditional methods.

With Workpulse, your staff can become more efficient in their tasks and managers can get 100% visibility for all equipment across all locations in real time.

To know more, schedule a call with our product consultants today.